Settleometer for ACTIVATED SLUDGE

“The ability to observe and measure the rate and characteristics of solids separation is essential to control biological treatment processes that produce sludge.”

Activated Sludge Manual of Practice OM-9

The Settleometer shows the solids liquid separation capability in the secondary clarifier. Sludge must separate from the liquid for settling to occur. Settling of sludge in the clarifier is a critical part of the activated sludge process. Poorly settling sludge is a strong indication of process problems and solids loss in final effluent.

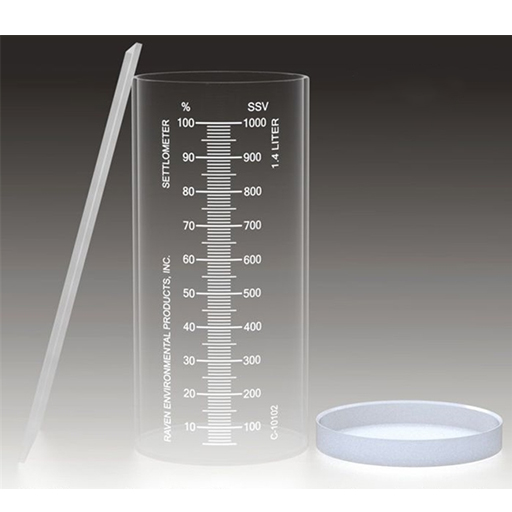

The scale printed on the Settleometer measures how far a sample has settled. “SSV” is the abbreviation for Settled Sludge Volume. “%” shows the settled sludge volume as a percentage of the entire sample. The sample to the right has a SSV of 350 which is also 35% of the total sample volume.

Observe Settling Characteristics

Normal sludge forms a floc and gently squeezes the water out of the blanket forming on the bottom. Settles between 800 and 700 in five minutes. If there are excess solids in the final effluent with Normal sludge, a clarifier mechanical problem may exist. Rapid sludge settles like dark grains of sand leaving behind a turbid supernatant with suspended solids. Settles to 700 or less in five minutes. Slow sludge appears to be stuck in the settling process with little or no progress but with very clear supernatant. Does not settle to 800 in five minutes. Perform the Multi-Dilution test to determine if slow settling is caused by density or concentration.

Troubleshooting Slow Sludge

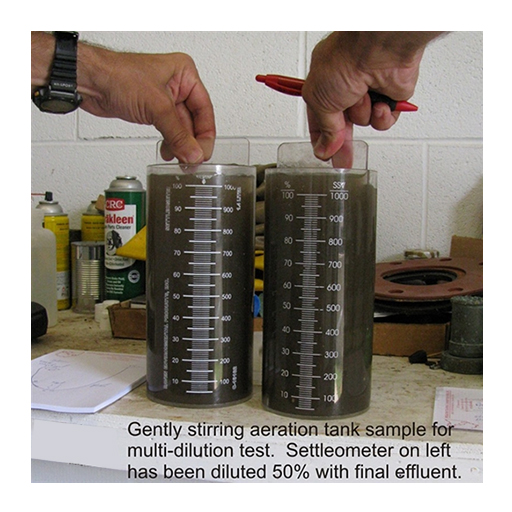

Slow settling sludge can be caused by high density sludge or high concentrations of sludge. The Multi-Dilution Test is performed with two Settleometers.

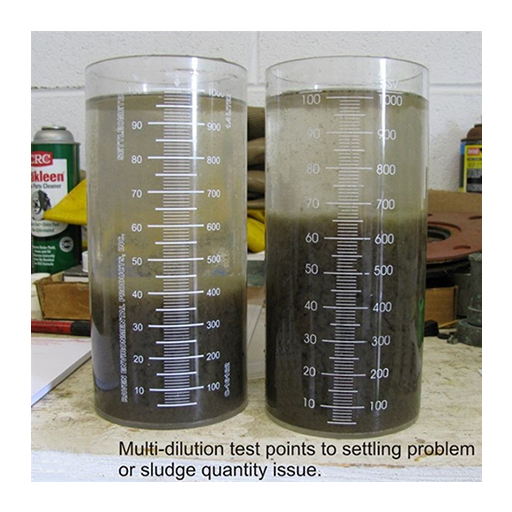

- Density Issue – If the sludge in the diluted Settleometer settles the same as the sludge in the pure Settlometer, this indicates a density issue. Density is related to sludge character. Reducing the pure sample by 50% did not affect the settling characteristic. In other words, the amount of sludge in the sample did not affect the settling. A density issue should be tested further with microscopic evaluation to determine if filamentous sludge is a problem.

- Concentration Issue – If the sludge in the diluted Settleometer settles significantly more than the sludge in the pure Settleometer, this indicates a concentration issue. Concentration is related to sludge quantity. Reducing the pure sample by 50% allowed the sludge to settle further. In other words, the sludge was simply piling up in the pure sample.

Application to Process Control

The Settleometer is used in wastewater plants for primarily four applications:

- Settling characteristics – Rapid, Normal or Slow settling.

- SSV is used in calculating return sludge flow rates.

- Troubleshooting settling problems to determine a density or a concentration issue.

- Timing when denitrification occurs and sludge rises to surface of Settleometer.

Settleometer for ACTIVATED SLUDGE

“The ability to observe and measure the rate and characteristics of solids separation is essential to control biological treatment processes that produce sludge.”

Activated Sludge Manual of Practice OM-9

The Settleometer shows the solids liquid separation capability in the secondary clarifier. Sludge must separate from the liquid for settling to occur. Settling of sludge in the clarifier is a critical part of the activated sludge process. Poorly settling sludge is a strong indication of process problems and solids loss in final effluent.

The scale printed on the Settleometer measures how far a sample has settled. “SSV” is the abbreviation for Settled Sludge Volume. “%” shows the settled sludge volume as a percentage of the entire sample. The sample to the right has a SSV of 350 which is also 35% of the total sample volume.

Observe Settling Characteristics

Normal sludge forms a floc and gently squeezes the water out of the blanket forming on the bottom. Settles between 800 and 700 in five minutes. If there are excess solids in the final effluent with Normal sludge, a clarifier mechanical problem may exist. Rapid sludge settles like dark grains of sand leaving behind a turbid supernatant with suspended solids. Settles to 700 or less in five minutes. Slow sludge appears to be stuck in the settling process with little or no progress but with very clear supernatant. Does not settle to 800 in five minutes. Perform the Multi-Dilution test to determine if slow settling is caused by density or concentration.

Troubleshooting Slow Sludge

Slow settling sludge can be caused by high density sludge or high concentrations of sludge. The Multi-Dilution Test is performed with two Settleometers.

- Density Issue – If the sludge in the diluted Settleometer settles the same as the sludge in the pure Settlometer, this indicates a density issue. Density is related to sludge character. Reducing the pure sample by 50% did not affect the settling characteristic. In other words, the amount of sludge in the sample did not affect the settling. A density issue should be tested further with microscopic evaluation to determine if filamentous sludge is a problem.

- Concentration Issue – If the sludge in the diluted Settleometer settles significantly more than the sludge in the pure Settleometer, this indicates a concentration issue. Concentration is related to sludge quantity. Reducing the pure sample by 50% allowed the sludge to settle further. In other words, the sludge was simply piling up in the pure sample.

Application to Process Control

The Settleometer is used in wastewater plants for primarily four applications:

- Settling characteristics – Rapid, Normal or Slow settling.

- SSV is used in calculating return sludge flow rates.

- Troubleshooting settling problems to determine a density or a concentration issue.

- Timing when denitrification occurs and sludge rises to surface of Settleometer.