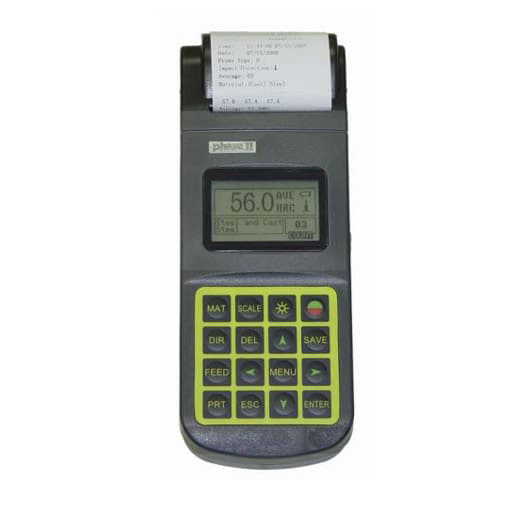

Phase II PHT-3500 portable hardness tester with printer is a state-of-the-art digital tester

It is designed to test the hardness of large hard metal parts. Loaded with useful functions and a built-in mini-printer that allows for easy record keeping. The PHT-3500 is clearly the industry leader for fast accurate hardness testing with an advanced USB output and thermal printing capabilities.

The PHT-3500 can perform tests that easily convert to the most popular hardness scales, including Rockwell, Brinell, Vickers, Shore, etc.

Operation:

- Load the impact body

- Place the impact body on your test piece

- Push the button to begin testing and obtain a reading

Standard Accessories:

- Base instrument

- Impact device D

- Calibrated test block

- Custom carry case

- Cleaning brush

- Operation manual

Optional accessories:

- Impact devices, DC, D+15, DL, G, C

- Special support rings

- Mini printer

Functions:

- Easy to use keypad operation

- Auto identification of Impact Device

- Large LCD display with backlight

- USB Output

- Automatic conversions to: Brinell, Rockwell B & C, Vicker and Shore

- Automatic mean value as well as Min & Max values

- Battery indicator

- Memory capacity ( 100 groups)

Specifications:

- Accuracy: +/- 0.5% (referred to L=800

- Repeatability accuracy: +/- 4L units) L=Leeb

- Measuring range: 200-960 HL

- Materials: steel & cast, alloy tool steel, stainless steel, grey cast iron, spheroidal iron, cast aluminum, brass, bronze, wrought copper alloy.

- Battery type: Rechargeable

- Operating temperature: 5-104 degrees F

- Dimensions: 150 x 74 x 32mm

- Weight: 245 grams

Special Application Impact Devices

Impact Device D

Universal standard device:

Use for the majority of hardness testing assignments

Impact Device DL (not shown)

Needle front section .109” diameter x 1.96” length

Measurements in extremely confined spaces

Impact Device G

Enlarged test tip: For use on solid heavy components such as; rough castings and forgings. Brinell only.

Impact Device DC

Extremely short impact device

Used for very confined spaces such as holes, cylinders, internal measurements

Impact Device D+15

Slim front section with coil set back.

Hardness measurements in grooves, recessed surface.

Impact Device C

Reduced impact energy

For testing case hardened or thin-walled components

QUICK TIP:

Safety Instructions:

- The instrument can only work with the specially designed battery pack and power adapter (charger) supplied with the PHT-3500. Working with others may result in damage of the instrument, battery leakage, and / or fire.

- Do not cast the battery pack into the

Hardware > Tools > Measuring Tools & Sensors > Gauges

fire and do not short circuit, disassemble or heat the battery pack, otherwise battery leakage, fire or even explosion may occur.

- Do not open the cover of the paper compartment or come into contact with the heating head of the printer by hand or any part of your body to avoid burns due to high temperature when the printer is printing.

Phase II PHT-3500 portable hardness tester with printer is a state-of-the-art digital tester

It is designed to test the hardness of large hard metal parts. Loaded with useful functions and a built-in mini-printer that allows for easy record keeping. The PHT-3500 is clearly the industry leader for fast accurate hardness testing with an advanced USB output and thermal printing capabilities.

The PHT-3500 can perform tests that easily convert to the most popular hardness scales, including Rockwell, Brinell, Vickers, Shore, etc.

Operation:

- Load the impact body

- Place the impact body on your test piece

- Push the button to begin testing and obtain a reading

Standard Accessories:

- Base instrument

- Impact device D

- Calibrated test block

- Custom carry case

- Cleaning brush

- Operation manual

Optional accessories:

- Impact devices, DC, D+15, DL, G, C

- Special support rings

- Mini printer

Functions:

- Easy to use keypad operation

- Auto identification of Impact Device

- Large LCD display with backlight

- USB Output

- Automatic conversions to: Brinell, Rockwell B & C, Vicker and Shore

- Automatic mean value as well as Min & Max values

- Battery indicator

- Memory capacity ( 100 groups)

Specifications:

- Accuracy: +/- 0.5% (referred to L=800

- Repeatability accuracy: +/- 4L units) L=Leeb

- Measuring range: 200-960 HL

- Materials: steel & cast, alloy tool steel, stainless steel, grey cast iron, spheroidal iron, cast aluminum, brass, bronze, wrought copper alloy.

- Battery type: Rechargeable

- Operating temperature: 5-104 degrees F

- Dimensions: 150 x 74 x 32mm

- Weight: 245 grams

Special Application Impact Devices

Impact Device D

Universal standard device:

Use for the majority of hardness testing assignments

Impact Device DL (not shown)

Needle front section .109” diameter x 1.96” length

Measurements in extremely confined spaces

Impact Device G

Enlarged test tip: For use on solid heavy components such as; rough castings and forgings. Brinell only.

Impact Device DC

Extremely short impact device

Used for very confined spaces such as holes, cylinders, internal measurements

Impact Device D+15

Slim front section with coil set back.

Hardness measurements in grooves, recessed surface.

Impact Device C

Reduced impact energy

For testing case hardened or thin-walled components

QUICK TIP:

Safety Instructions:

- The instrument can only work with the specially designed battery pack and power adapter (charger) supplied with the PHT-3500. Working with others may result in damage of the instrument, battery leakage, and / or fire.

- Do not cast the battery pack into the

Hardware > Tools > Measuring Tools & Sensors > Gauges

fire and do not short circuit, disassemble or heat the battery pack, otherwise battery leakage, fire or even explosion may occur.

- Do not open the cover of the paper compartment or come into contact with the heating head of the printer by hand or any part of your body to avoid burns due to high temperature when the printer is printing.