The Abrasion tester is used to evaluate a material’s resistance to wear, a flat specimen is mounted to a turntable platform that rotates on a vertical axis.

“Taber Test” delivers reliable data in minutes.

As the turntable rotates, contact of the specimen against the sliding rotation of two abrading wheels cause wear while a vacuum system removes loose wear debris during the test. The resulting abrasion marks form a pattern of crossed arcs in a circular band that cover an area approximately 30 cm2

- LCD operator touch screen

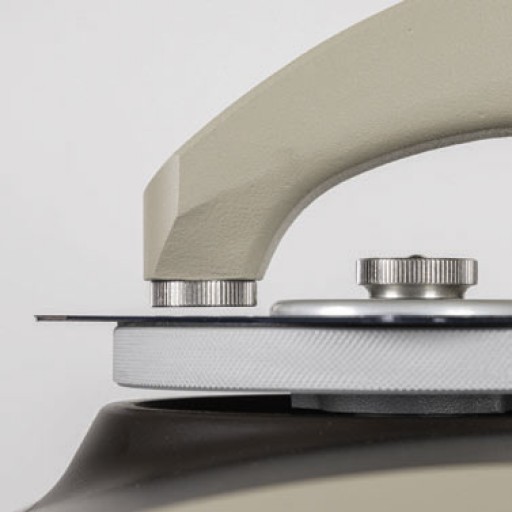

- Quick release wheel mounting hub

- Critical components easy to replace

- Compact abraser arm assemblies

- Redesigned support frame and housing

- Direct flow vacuum nozzle with precision height adjustment

- Screw-in vacuum nozzle tips for 8 mm and 11 mm

- Selectable display options (including language)

- Store test profiles

REFERENCED IN MORE THAN 100 INTERNATIONAL TEST STANDARDS AND SPECIFICATIONS

TABER ROTARY ABRASER INCLUDES:

- Auxiliary Weights provide 500g & 1000g load

- Specimen Holder (SH-125)

- Hold Down Ring (SH-101)

- Vacuum Unit with Suction Hose (not shown)

LCD OPERATOR TOUCH SCREEN

Provides enhanced user experience with an easy-to-use operator interface

The Abrasion tester is used to evaluate a material’s resistance to wear, a flat specimen is mounted to a turntable platform that rotates on a vertical axis.

“Taber Test” delivers reliable data in minutes.

As the turntable rotates, contact of the specimen against the sliding rotation of two abrading wheels cause wear while a vacuum system removes loose wear debris during the test. The resulting abrasion marks form a pattern of crossed arcs in a circular band that cover an area approximately 30 cm2

- LCD operator touch screen

- Quick release wheel mounting hub

- Critical components easy to replace

- Compact abraser arm assemblies

- Redesigned support frame and housing

- Direct flow vacuum nozzle with precision height adjustment

- Screw-in vacuum nozzle tips for 8 mm and 11 mm

- Selectable display options (including language)

- Store test profiles

REFERENCED IN MORE THAN 100 INTERNATIONAL TEST STANDARDS AND SPECIFICATIONS

TABER ROTARY ABRASER INCLUDES:

- Auxiliary Weights provide 500g & 1000g load

- Specimen Holder (SH-125)

- Hold Down Ring (SH-101)

- Vacuum Unit with Suction Hose (not shown)

LCD OPERATOR TOUCH SCREEN

Provides enhanced user experience with an easy-to-use operator interface