The HI96831 is a digital refractometer for ethylene glycol to measure the percent volume and freezing point on solutions.

- Designed for ethylene glycol analysis

- Automatic Temperature Compensation

- 0 – 100% Volume range with ±0.2% accuracy

- 0 to -50 °C freezing point range with ±0.5 °C accuracy

The HI96831 has a high accuracy of ±0.2% volume and ±0.5 °C freezing point and features a simple operation that gives reliable results each and every time. All readings are automatically compensated for temperature variations and displayed within a 1.5 second response time.

The sealed flint glass prism and stainless steel well are easy to clean. Just wipe with a soft cloth in preparation for the next sample.

Learn About the HI96831 Digital Refractometer Ethylene Glycol

HI96831 Hanna pH meter with superior accuracy

| Ethylene Glycol Range | 0 to 100% |

|---|---|

| Ethylene Glycol Resolution | 0.1 % |

| Ethylene Glycol Accuracy | ±0.2 % |

| Temperature Range | 0 to 80°C (32 to 176°F) |

| Temperature Resolution | 0.1°C (0.1°F) |

| Temperature Accuracy | ±0.3 °C (±0.5 °F) |

| Temperature Compensation | automatic between 0 and 40°C (32 to 104°F) |

| Automatic Shut-Off | after three minutes of inactivity |

| Battery Type/Life | 9V / approximately 5000 readings |

| Dimensions | 192 x 102 x 67 mm (7.6 x 4.01 x 2.6”) |

| Weight | 420 g (14.8 oz.) |

| Refractometer Light Source | yellow LED |

| Minimum Sample Volume | 100 μL (to cover prism totally) |

| Sample Cell | stainless steel ring and flint glass prism |

| Measurement Time | approximately 1.5 seconds |

| Ordering Information | HI96831 is supplied with a battery and instruction manual |

| Notes | Enclosure Rating: IP65 |

The HI96831 Digital Refractometer for Ethylene Glycol utilizes the measurement of refractive index to determine the percent volume and freezing points of ethylene glycol-based solutions.

Ethylene glycol is used in glycol cooling systems for industrial applications. Maintaining the appropriate percent of glycol is important in glycol chillers as too low of a percentage could lead to the system freezing and rupturing while too much glycol will reduce the system’s efficiency.

The instrument converts the refractive index of a sample to percent volume or freezing point. These conversions are based on internationally recognized references for unit conversion and temperature compensation for glycol solutions (e.g. CRC Handbook of Chemistry and Physics, 87th Edition). The HI96831 is an easy-to-use tool for measuring freezing point and percent volume in ethylene glycol solutions, in the field or in the lab.

Making a Standard Solution

To make an Ethylene Glycol Solution, follow the procedure below:

- Place container (such as a glass vial or dropper bottle that has a cover) on an analytical balance.

- Tare the balance.

- Volumetrically add X mL of high purity ethylene glycol (CAS #: 107-21-1; MW 62.068) to a 100 mL Grade A volumetric flask.

- Use distilled or deionized water to bring the flask close to the total volume, mix, allow the solution to return to room temperature.

- Once the solution has returned to room temperature use distilled or deionized water to bring the total volume to 100 mL. Mix solution well before use.

| Ethylene Glycol | Total Volume | Expected Freezing Point Value | |

| 10% V/V | 10.00 mL | 100.00 mL | -3.8 °C (25.2 °F) |

| 40% V/V | 40.00 mL | 100.00 mL | -26.3 °C (-15.4 °F) |

Measurement Units

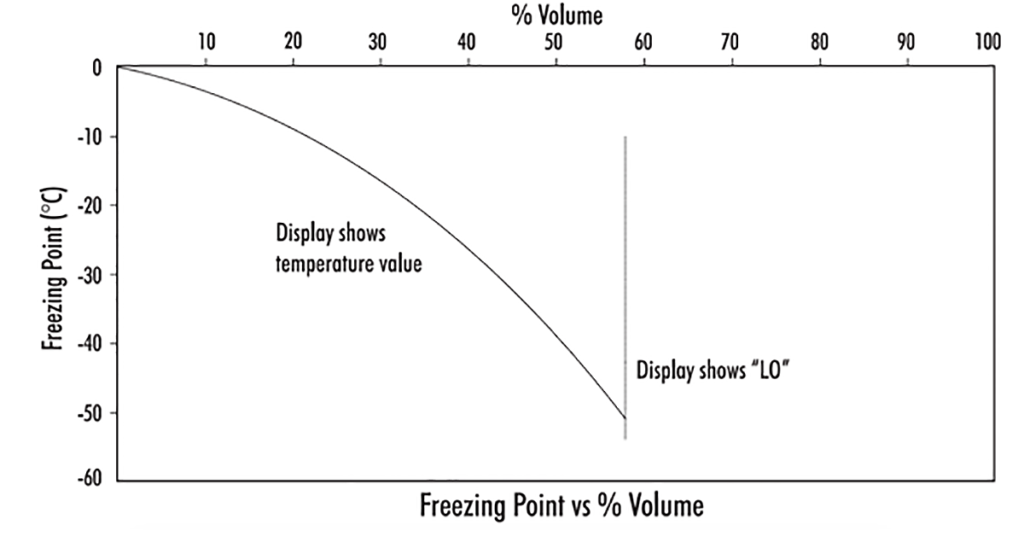

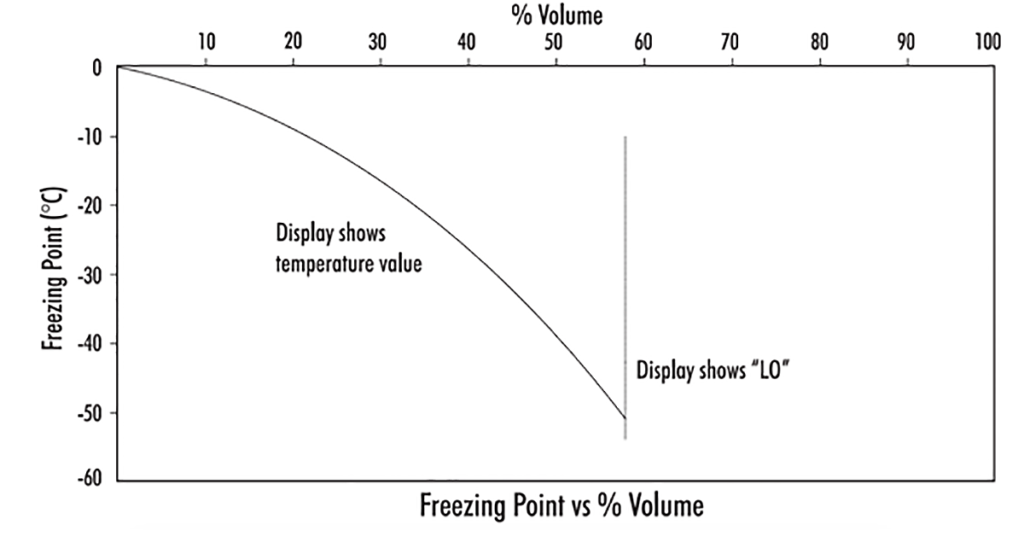

The freezing point is displayed as a temperature from 0.0 to -50.0 °C corresponding to 0-58 % by volume. The display blinks the freezing point when the concentration of Ethylene glycol is greater than 78 % concentration by volume. When the display shows “LO”, the freezing point is at a minimum (below -50 °C).

Refractive Index

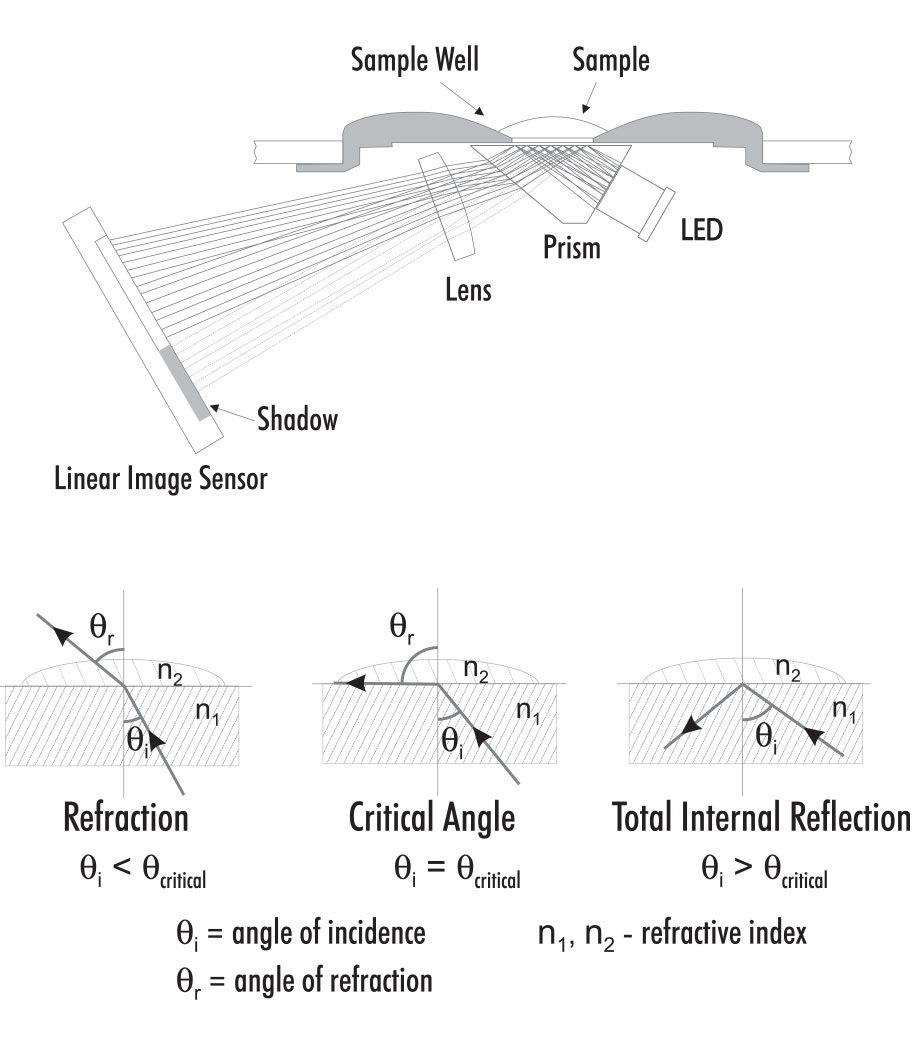

The HI96831 takes measurements based on a sample’s refractive index. A Refractive index is a measurement of how light behaves as it passes through the sample. Depending on the sample’s composition, light will refract and reflect differently. By measuring this activity with a linear image sensor, the sample’s refractive index can be assessed and used to determine its physical properties such as concentration and density. In addition to the linear image sensor, the HI96831 uses an LED light, prism, and lens to make measurement possible.

Variations in temperature will affect the accuracy of refractometry readings, so the use of temperature compensation is highly recommended for reliable results. The HI96831 contains a built-in temperature sensor and is programmed with temperature compensation algorithms in accordance with internationally recognized references which vary based on the parameter being measured.

Features at-a-glance:

One-point calibration

- Calibrate with distilled or deionized water

Small sample size

- Sample size can be as small as 2 metric drops (100 μl)

Automatic Temperature Compensation (ATC)

- Samples automatically compensated for temperature variations

Quick, accurate results

- Readings are displayed in approximately 1.5 seconds

Dual-level LCD

- The dual-level LCD displays measurements and temperature readings simultaneously

Stainless steel sample well

- Easy to clean and corrosion-resistant

Battery indicators

- Battery percent level remaining at startup and low battery indicator

Automatic shut-off

- To conserve battery life the meter shuts off automatically after three minutes of non-use

IP65 water-resistant protection

- Water-resistant ABS plastic casing designed to perform under laboratory and field conditions.

QUICK TIP:

Measurement Procedure

1. Wipe off the prism surface located at the bottom of the sample well. Make sure the prism and sample well are completely dry.

2. Using a plastic pipette, drip the sample onto the prism surface. Fill the well completely. Note: If the temperature of the sample differs significantly from the temperature of the instrument, wait approximately 1 minute to allow thermal equilibration.

3. Press the READ key. The results are displayed as % Volume or Freezing Point.

Note: The last measurement value will be displayed until the next sample is measured or the instrument is turned off. The temperature will be continuously updated. The ATC tag blinks and automatic temperature compensation is disabled if the temperature exceeds the 0.0-40.0 ºC /32.0-104.0 ºF range.

4. Remove the sample from the sample well by absorbing it with a soft tissue.

5. Using a plastic pipette, rinse prism and sample well with distilled or deionized water. Wipe dry. The instrument is ready for the next sample.

Learn more in the Instruction Manual / Quick Start Guide.

The HI96831 is a digital refractometer for ethylene glycol to measure the percent volume and freezing point on solutions.

- Designed for ethylene glycol analysis

- Automatic Temperature Compensation

- 0 – 100% Volume range with ±0.2% accuracy

- 0 to -50 °C freezing point range with ±0.5 °C accuracy

The HI96831 has a high accuracy of ±0.2% volume and ±0.5 °C freezing point and features a simple operation that gives reliable results each and every time. All readings are automatically compensated for temperature variations and displayed within a 1.5 second response time.

The sealed flint glass prism and stainless steel well are easy to clean. Just wipe with a soft cloth in preparation for the next sample.

Learn About the HI96831 Digital Refractometer Ethylene Glycol

HI96831 Hanna pH meter with superior accuracy

| Ethylene Glycol Range | 0 to 100% |

|---|---|

| Ethylene Glycol Resolution | 0.1 % |

| Ethylene Glycol Accuracy | ±0.2 % |

| Temperature Range | 0 to 80°C (32 to 176°F) |

| Temperature Resolution | 0.1°C (0.1°F) |

| Temperature Accuracy | ±0.3 °C (±0.5 °F) |

| Temperature Compensation | automatic between 0 and 40°C (32 to 104°F) |

| Automatic Shut-Off | after three minutes of inactivity |

| Battery Type/Life | 9V / approximately 5000 readings |

| Dimensions | 192 x 102 x 67 mm (7.6 x 4.01 x 2.6”) |

| Weight | 420 g (14.8 oz.) |

| Refractometer Light Source | yellow LED |

| Minimum Sample Volume | 100 μL (to cover prism totally) |

| Sample Cell | stainless steel ring and flint glass prism |

| Measurement Time | approximately 1.5 seconds |

| Ordering Information | HI96831 is supplied with a battery and instruction manual |

| Notes | Enclosure Rating: IP65 |

The HI96831 Digital Refractometer for Ethylene Glycol utilizes the measurement of refractive index to determine the percent volume and freezing points of ethylene glycol-based solutions.

Ethylene glycol is used in glycol cooling systems for industrial applications. Maintaining the appropriate percent of glycol is important in glycol chillers as too low of a percentage could lead to the system freezing and rupturing while too much glycol will reduce the system’s efficiency.

The instrument converts the refractive index of a sample to percent volume or freezing point. These conversions are based on internationally recognized references for unit conversion and temperature compensation for glycol solutions (e.g. CRC Handbook of Chemistry and Physics, 87th Edition). The HI96831 is an easy-to-use tool for measuring freezing point and percent volume in ethylene glycol solutions, in the field or in the lab.

Making a Standard Solution

To make an Ethylene Glycol Solution, follow the procedure below:

- Place container (such as a glass vial or dropper bottle that has a cover) on an analytical balance.

- Tare the balance.

- Volumetrically add X mL of high purity ethylene glycol (CAS #: 107-21-1; MW 62.068) to a 100 mL Grade A volumetric flask.

- Use distilled or deionized water to bring the flask close to the total volume, mix, allow the solution to return to room temperature.

- Once the solution has returned to room temperature use distilled or deionized water to bring the total volume to 100 mL. Mix solution well before use.

| Ethylene Glycol | Total Volume | Expected Freezing Point Value | |

| 10% V/V | 10.00 mL | 100.00 mL | -3.8 °C (25.2 °F) |

| 40% V/V | 40.00 mL | 100.00 mL | -26.3 °C (-15.4 °F) |

Measurement Units

The freezing point is displayed as a temperature from 0.0 to -50.0 °C corresponding to 0-58 % by volume. The display blinks the freezing point when the concentration of Ethylene glycol is greater than 78 % concentration by volume. When the display shows “LO”, the freezing point is at a minimum (below -50 °C).

Refractive Index

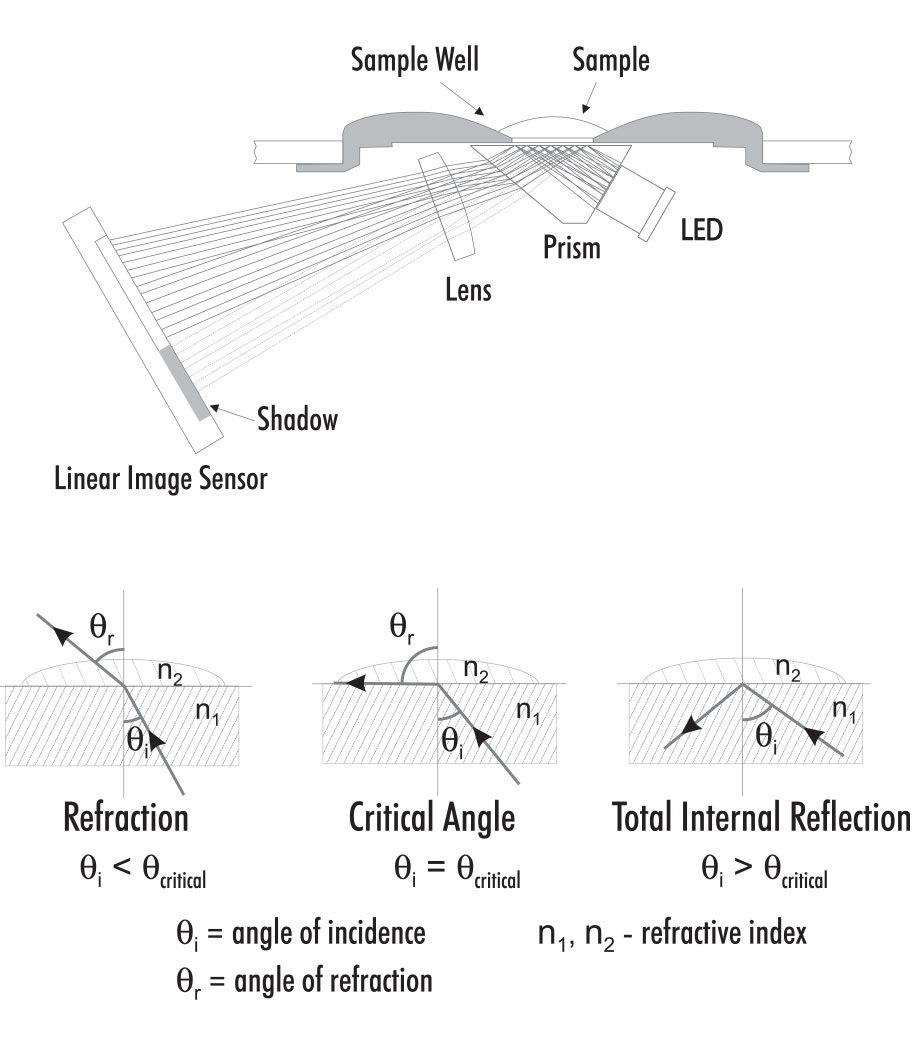

The HI96831 takes measurements based on a sample’s refractive index. A Refractive index is a measurement of how light behaves as it passes through the sample. Depending on the sample’s composition, light will refract and reflect differently. By measuring this activity with a linear image sensor, the sample’s refractive index can be assessed and used to determine its physical properties such as concentration and density. In addition to the linear image sensor, the HI96831 uses an LED light, prism, and lens to make measurement possible.

Variations in temperature will affect the accuracy of refractometry readings, so the use of temperature compensation is highly recommended for reliable results. The HI96831 contains a built-in temperature sensor and is programmed with temperature compensation algorithms in accordance with internationally recognized references which vary based on the parameter being measured.

Features at-a-glance:

One-point calibration

- Calibrate with distilled or deionized water

Small sample size

- Sample size can be as small as 2 metric drops (100 μl)

Automatic Temperature Compensation (ATC)

- Samples automatically compensated for temperature variations

Quick, accurate results

- Readings are displayed in approximately 1.5 seconds

Dual-level LCD

- The dual-level LCD displays measurements and temperature readings simultaneously

Stainless steel sample well

- Easy to clean and corrosion-resistant

Battery indicators

- Battery percent level remaining at startup and low battery indicator

Automatic shut-off

- To conserve battery life the meter shuts off automatically after three minutes of non-use

IP65 water-resistant protection

- Water-resistant ABS plastic casing designed to perform under laboratory and field conditions.

QUICK TIP:

Measurement Procedure

1. Wipe off the prism surface located at the bottom of the sample well. Make sure the prism and sample well are completely dry.

2. Using a plastic pipette, drip the sample onto the prism surface. Fill the well completely. Note: If the temperature of the sample differs significantly from the temperature of the instrument, wait approximately 1 minute to allow thermal equilibration.

3. Press the READ key. The results are displayed as % Volume or Freezing Point.

Note: The last measurement value will be displayed until the next sample is measured or the instrument is turned off. The temperature will be continuously updated. The ATC tag blinks and automatic temperature compensation is disabled if the temperature exceeds the 0.0-40.0 ºC /32.0-104.0 ºF range.

4. Remove the sample from the sample well by absorbing it with a soft tissue.

5. Using a plastic pipette, rinse prism and sample well with distilled or deionized water. Wipe dry. The instrument is ready for the next sample.

Learn more in the Instruction Manual / Quick Start Guide.